Current advancements working with carbon nanotube electrodes show the capacity for multifunctionality as a lithium-ion storage material and as an electrically conductive support for other high capacity materials like silicon or germanium. It is recognized that the inclusion of carbon as an additive in the creation of electrodes, or as a coating of the electrodes enhances the electronic conductivity and capacity efficiency of Li-ion and other battery systems. Paper Battery Company’s technology is based on never-noticed-before combinations of supercapacitor power and energy densities, combined with ultrathin footprints and placement options. The next step in the method is to cycle the battery while in TEM so that the reside deterioration can be observed.

Current advancements working with carbon nanotube electrodes show the capacity for multifunctionality as a lithium-ion storage material and as an electrically conductive support for other high capacity materials like silicon or germanium. It is recognized that the inclusion of carbon as an additive in the creation of electrodes, or as a coating of the electrodes enhances the electronic conductivity and capacity efficiency of Li-ion and other battery systems. Paper Battery Company’s technology is based on never-noticed-before combinations of supercapacitor power and energy densities, combined with ultrathin footprints and placement options. The next step in the method is to cycle the battery while in TEM so that the reside deterioration can be observed.

Because of the big surface area and porous structure of the nanotube electrodes, there are a lot of areas for the ions to react, and they can travel in and out quickly, which gives the nanotube battery higher power capacity and power, says Shao-Horn. Please contact a Paper Battery Corporation representative to discover how these capabilities can help your design’s desires for minimizing each time-to-market and Bill of Supplies expense and count.

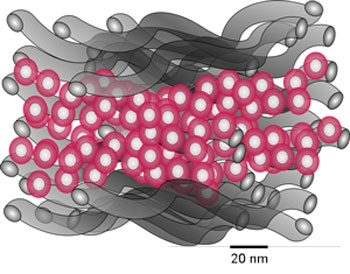

However, the UW-Madison researchers pioneered a new method, called floating evaporative self-assembly, or FESA, which they described earlier in 2014 in the ACS journal Langmuir In that method, researchers exploited a self-assembly phenomenon triggered by swiftly evaporating a carbon nanotube answer. The Paper Battery Business has created a game changing ultrathin supercapacitor with business-top efficiency.

In 2007, the first cross-sectional observation of an all solid state Li-ion nanobattery was taken by TEM ( transmission electron microscopy ), with consideration to the deterioration of interior interfaces under cycling , as component of the common effort to identify the underlying causes of battery deterioration. It is recognized to use materials referred to as carbon nanofibers,” which are similar to carbon nanotubes, in lithium batteries. Now, the group from MIT says that carbon nanotubes have established they could hold the key to super-effective or super-lightweight batteries in the future.

The power output for a offered weight of this new electrode material is over 5 occasions greater than for traditional electrochemical capacitors whilst the total energy delivery capability approaches ten instances that of lithium-ion batteries. It is consequently to an improved lithium-ion battery that has single wall carbon nanotubes to improve electrochemical functionality that the present invention is mostly directed. Ahead of going freelance, I was MIT Technologies Review’s material science editor and I graduated from MIT’s Science Writing program in 2004.